Textiles comprise a staggering percentage of global waste. You may have heard the stats:

- 92 million tonnes of the 100 billion garments produced each year will end up in landfills that same year.

- The average American throws away 81.15 lbs of clothes per year.

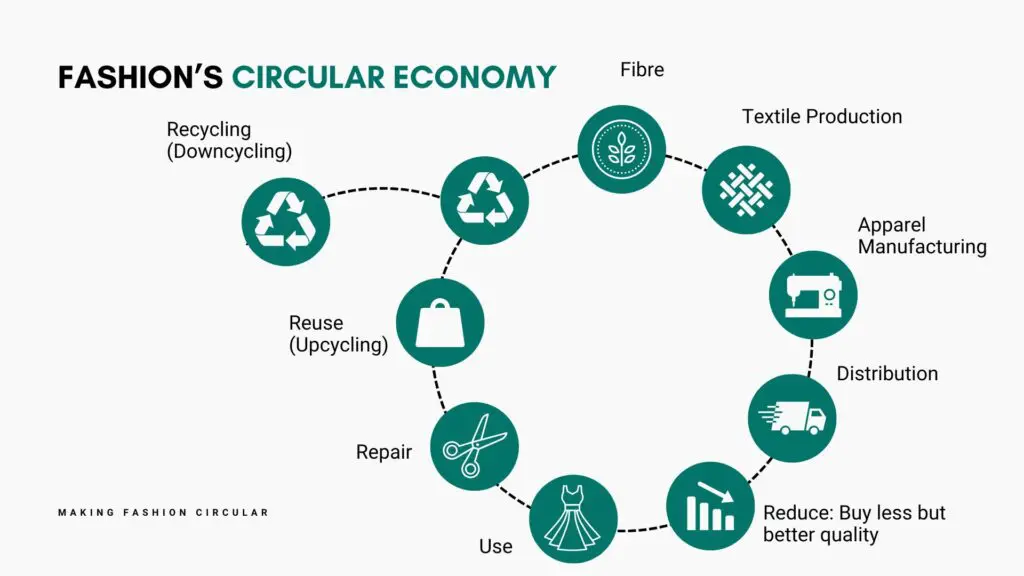

The industry, as it stands, is supported by the linear economy model whereby products follow a “Take Make Waste” pattern. Experts affirm that in order to shift away from this destructive pattern of production, consumption, and disposal, we must embrace a different approach, namely, a “circular economy”.

What is a Circular Economy?

In a circular economy, both raw material inputs and waste outputs are limited. Products are circulated through the economy through reuse and recycling to create a system more closely resembling a closed loop.

(Fashion’s Circular Economy (FTA, 2024))

One of the major hurdles in implementing circular economy principles is a disconnect between the beginning and end of life of a product.

Currently, producers and retailers manufacture and sell their products, and then, for the most part, relinquish all responsibility for them. There is no regulation in place to ensure that these products remain in use, and not simply disposed of. For textiles, this means that the responsibility lands on consumers and organizations independent from the original producers such as thrift stores or resale platforms. That management is generally only for textiles which maintain high market value (used garments that are still in good condition and desirable) and can support the entities’ operations. This disconnect — and lack of accountability— supports the linear model.

This is where Extended Producer Responsibility (EPR) Comes into Play

Extended Producer Responsibility (EPR) is a policy tool which shifts pressure onto producers to take responsibility for the entire lifecycle of their products (including end of life management). Under EPR programs, producers become responsible for collecting and processing their products once they’ve undergone their first cycle of use. EPR implements a financial framework to make management feasible for all discarded textiles and is considered by the Ellen MacArthur Foundation to be “a necessary part of the solution to achieve a circular economy for textiles.”

Generally, EPR programs present producers and retailers with two options: (1) Either they must establish their own system of collection and processing for products, or (2) they must join a Producer Responsibility Organization (PRO). A PRO facilitates a collection program for multiple producers. They are usually a nonprofit organization whose operations are funded through fees paid by the producers.

The goals of an EPR program pertain not only to end of life management, but also to essentially incentivizes circular design from the beginning — encouraging producers to reflect on the design of that product and prompt them to develop it with lower impact, durability and circularity in mind at the start. Often ‘ecomodulated fee structures’ are also incorporated into the program, whereby if a product is produced with sustainability in mind (for example, a garment made with 50% recycled content), a producer will receive a discount on fees. The fee structures associated with EPR are typically used to fund a reverse logistics sector for the processing of post consumer products, a crucial part of any circular system.

* Reverse Logistics Sector refers to the stage in the supply chain where products and materials are returned to producers and manufacturers and reprocessed, for recycling, reuse or disposal.

Challenges of EPR

Implementation: Setting up effective EPR systems can be complex and costly.

Market Participation: Ensuring that all producers participate can be difficult, especially with global supply chains.

Consumer Behaviour: Changing consumer habits regarding clothing use and disposal requires ongoing education.

The key to overcoming challenges associated with EPR is an effective and thoughtful legislation framework.

EPR History – Where Did This Come From?

Historically, EPR has been most visible in the packaging industry. When you buy a six pack of soda or beer, you can return the cans to a recycling depot and receive money back. This system is facilitated by an EPR program, specifically a deposit return scheme (DRS). On average, DRS is reported to recover 90% of containers, making it a highly effective tool to promote circularity. The graphic below from the Ellen MacArthur Foundation illustrates the difference between recycling rates in countries with and without EPR.

EPR in Canada

While the Canadian federal government has consulted with organizations like Fashion Takes Action (FTA) and National Association for Charitable Textile Recycling (NACTR) on the volumes of textile flows and feasibility of recycling in Canada, no concrete plans are in motion to implement it. In 2019, the government released the Canada-wide Action Plan on Zero Plastic Waste, and have since published a guide to “facilitate consistent extended producer responsibility policies and programs for plastics”

Each Canadian province manages its own waste programs, and some provinces have implemented EPR. British Columbia, for example, currently has programs in place for hybrid and electric vehicle batteries and other types; mattresses and foundations; more electronics; and moderately hazardous products (e.g., medical sharps, single-use canisters). They are also evaluating Industrial, Commercial and Institutional (IC&I) packaging and paper management as a future area to regulate. As yet, however, no province has coordinated a comprehensive textile management program.

EPR Globally

While many countries have implemented EPR policies for other sectors, few have a program for textiles. In Europe, this is about to change. In February 2024, the European Union passed a proposal to make EPR mandatory in member states. Countries have 18 months from the time of passing to implement the new regulations for producers (July 2025). Additionally, they have until January 2025 to set up a separate collection system for textile processing (through reuse, preparation for recycling and recycling). The figure below from the Ellen MacArthur Foundation maps where textile EPR systems currently exist and are proposed.

(We need Extended Producer Responsibility (EPR) policy for textiles, Ellen Macarthur Foundation)

Let’s take a closer look at some of these countries…

France

France has proven itself to be a trailblazer in this space. In 2007, they became the first country to implement a mandatory EPR program for textiles. The framework for this program is as follows:

All manufacturers, importers, and distributors must either join a PRO or set up a take back program approved by the legislative body (for example, H&M has its own take back program). The principal PRO is Refashion, responsible for 95% of the market with over 4000 registered members. Refashion charges brands/retailers fees which cover reuse and recycling costs. The fee structure is based on the volume and size of units the company put on the market the previous year.

There are four categories for garments (very small, small, medium and large) and two for shoes (small and medium). Refashion manages around 44,000 collection points across the country in public spaces (markets, malls, parking spaces, charitable orgs etc). Collected textiles are sorted and then resold, donated, recycled and/or exported.

The Netherlands

In 2023, the Netherlands also introduced an EPR program through the “Dutch EPR Decree”.

Under the decree, producers and importers must report their expected volume of textiles to be placed on the market, create a discarded textile collection system and process given percentages of the textiles for recycling and reuse respectively. A further percentage of that fraction for reuse must also be for reuse within the Netherlands.

There are two PROs producers can choose to join, Stichting UPV Textiel and the European Recycling Platform. The government has set increasing targets for the volume of textiles recovered.

Targets:

- By 2025, producers must process 50% (75% by 2030) of the previous year’s total weight sold, for reuse or recycling.

- At least 20% (25% by 2030) of this must be reused and 10% (15% by 2030) must be reused within the Netherlands

- By 2025, 25% (33% by 2030) of all the textile fibres from discarded textile products must be used in fibre to fibre recycling for new products.

Hungary

Hungary also established EPR for textiles in 2023. Their program is based around reporting and fees. All producers and importers (including e-commerce) are required to register with the National Waste Management Authority of the National Inspectorate for Environment and Nature (NWMD) and then register with the country’s PRO, MOHU MOL Hulladékgazdálkodási Zrt. (MOHU). Companies pay quarterly fees based on the category/quantity of goods they produce. A fee set by the government is calculated based on the weight of a given item multiplied by the fee factor. Producers report quarterly on the quantity of products manufactured.

Latvia

Latvia is the latest country to implement EPR for textiles. Producers and importers (including e-commerce) that put textiles on the Latvian market now have to pay a Natural Resource Tax (NRT). The tax is 0.5 EUR per kilogram of the products to fund the processing and recycling of textiles.

USA: California

The American state of California made waves this past month when it passed Bill SB-707, the California Responsible Textile Recovery Act. Under the bill, producers must form or join a PRO who will implement a complete stewardship plan for the collection and processing of products. The PRO must also establish a statewide education program to educate consumers and encourage participation in the collection scheme. For more details on this bill and its impacts, check out our Industry Brief on SB-707.

Limitations of EPR

National EPR systems are an effective tool to create a more circular economy. There are limitations, however, to EPR as a result of current limitations in the reverse logistics sector.

In many cases, recycling technology is not scalable to the extent that it needs to be to support a national program. EPR textile programs collect and process discarded textiles, ensuring these textiles aren’t ending up in a landfill. What happens after this, however, can begin to again replicate the linear economy model. Most notably, a common practice is to export the processed textiles to other countries, thus shifting the burden and applying unnecessary pressure on other countries’ processing and disposal systems, not to mention many of the countries that are on the receiving end for these textiles lack the infrastructure to properly manage the volumes of textiles arriving in their ports.

Even France, cited as an example of what effective textile EPR can look like, exports up to 80% of collected textiles. Some organizations, such as the Or Foundation in Ghana, are working to address the injustices perpetuated by this offloading. For EPR to be truly effective however, as well as to embody circular economy principles, this issue needs to be addressed on a systems level. Clearly there is a need to scale cross-border responsibility, internationally. Just as producers have a responsibility for their products, so too should the countries where those products are made, sold, and disposed of.

Extended Producer Responsibility for textiles is a key step on the journey to circularity. By attempting to minimize environmental impact and fostering responsibility among producers, it can shift not only waste disposal practices, but perspectives on “waste” and our culture of disposability. If we can overcome the challenges around implementation and innovate creative solutions for end of life, we will begin to move towards a more responsible, sustainable industry model where it becomes clear that caring for the planet is profitable.

ABOUT THE AUTHOR

Rebekah Stokes | Program Coordinator, Fashion Takes Action

Rebekah Stokes is the Program Coordinator at FTA. A Global Development student, her passion lies in creating real-world solutions to complex issues. She works to pivot current systems towards a more just and sustainable future. Read more…